Fossil fuels supply over 80 percent of the world’s primary energy and more than two-thirds of the world’s electricity. Of this, coal alone accounts for 40 percent of the global electricity supply. Though coal is well-distributed globally and provides stable and reliable energy on demand, it emits a large amount of carbon dioxide — a greenhouse gas that contributes to global warming. This attribute has prompted investigation into low-carbon alternatives. One such alternative involves capturing the carbon dioxide emitted by power plants and sequestering it. This technology would allow for the utilization of vast and widespread fuel resources (coal, oil, gas and biomass), which, unlike solar and wind power, are capable of delivering power on demand, while mitigating the potentially harmful effects of carbon dioxide (CO2).

First-generation carbon capture, utilization and storage (CCUS) is, however, expensive. To address this, LACER has been investigating pressurized oxy-combustion. Since the dew point of flue gas is higher at higher pressure than it is at atmospheric pressure, the latent heat of flue gas moisture can be utilized at high pressure to increase plant efficiency.

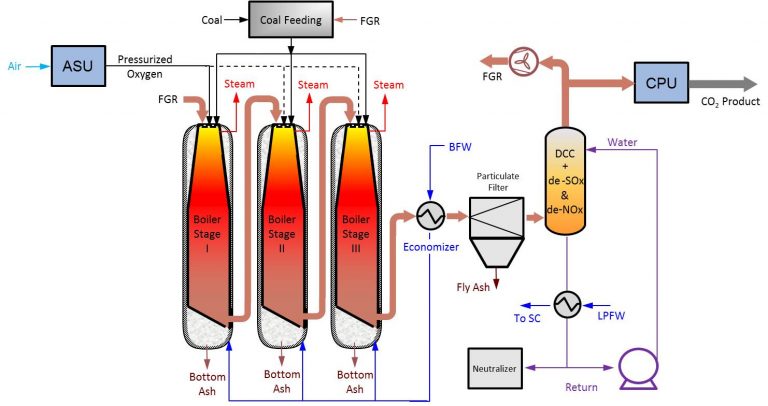

A new staged, pressurized oxy-combustion (SPOC) process for power generation with carbon capture is under development at LACER. The process not only extracts the flue gas moisture’s latent heat, but, unlike first-generation oxy-combustion, or even other pressurized oxy-combustion processes, it also minimizes the flue gas recycle. The net plant efficiency of this proposed process is more than 25 percent greater than that of first-generation oxy-combustion processes. A detailed analysis of capital and operating costs shows that the cost of electricity generated from this process would meet the U.S. Dept. of Energy’s target for power generation with carbon capture.

Nonetheless, the design of a low-recycle oxy-combustion boiler is not trivial. To this end, a new burner and boiler design is proposed. The proposed burner/boiler design:

- Accommodates low flue gas recycle without exceeding wall heat flux limits

- Increases the share of radiative over convective heat transfer in the boiler

- Significantly reduces ash fouling and slagging

- Is flexible, in that it is able to operate under various thermal loads

The proposed burner design also would reduce soot, as compared to a conventional burner. These aspects of the burner/boiler design are being investigated using computational fluid dynamics simulations and experiments in the lab and with a pilot-scale burner/combustor.