In 2016, petroleum products supplied 37 percent of America’s total primary energy consumption. Out of that, 71 percent was used for transportation and 23 percent went to industrial applications, with the rest used for residential and electric power applications. In the transportation sector, the vast majority of energy is supplied by fossil-derived liquid fuels, such as gasoline, diesel and aviation fuel. Liquid biofuels, such as ethanol and biodiesel, provide only about 5 percent of the total energy used for transportation.

Renewable alternatives to petroleum-based fuels are desirable as a means of reducing carbon dioxide (CO2) emissions. However, these alternatives can have drastically different properties than petroleum-based fuels, so any potential alternative must be thoroughly characterized and tested. Properties of interest include energy density, atomization behavior, vaporization and burning rates as well as chemical stability.

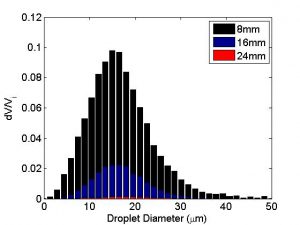

At LACER, we study the combustion of liquid fuels to understand how different fuel properties affect the combustion process from start to finish. We look at the spray breakup, droplet vaporization and size distribution, combustion temperature and exhaust composition. The understanding our research fosters allows for the characterization of promising alternative fuels and guides the development of future technologies.