Energy storage is among the 21st century’s principal challenges. Developing state-of-the-art, low-cost materials for electricity storage would pave the way for widespread adoption of electric vehicles and renewable energy.

Lithium-ion batteries are attractive for portable devices, electric and hybrid electric vehicles as well as for large renewable power facilities. Layer-structured materials such as lithium- and manganese-rich NMC or nickel-rich NMC622 have received considerable attention as high-capacity, low-cost and safe cathode materials for lithium-ion batteries. At LACER, we are developing flame-assisted spray pyrolysis to produce these materials.

The conventional synthesis method for these materials is coprecipitation, which has challenges associated with scale-up and cost. Therefore, spray pyrolysis is being developed as a scalable, low-cost alternative. Spray pyrolysis requires shorter residence times in the reactor, shorter annealing times, eliminates washing and purification steps and achieves excellent batch-to-batch reproducibility.

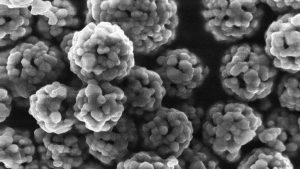

Due to the particle formation mechanism in spray pyrolysis, the product contains hollow spheres, which results in low bulk density. We are developing a scaled-up spray pyrolysis process for the synthesis of nonhollow lithium transition metal oxide materials. The method at present is capable of producing high-quality battery materials at a 60 gram/hour scale. High-energy layered oxides are produced with high tap density (> 1.2 g/cm3).